In the global wave of energy transition and green development, Hydro Power, as a core force of clean and renewable energy, is playing an increasingly important role. Max Hydro, as a professional service provider in the field of hydro power engineering, is committed to providing global hydro power plants with end-to-end solutions from "Water" to "Electricity" through technological innovation and customer needs. With the excellent products, customized services, and talent pool, it has firmly established as one of the leading service providers in the industry.

Core Business: Complete "Water-to-Electricity" Solutions, Empowering Green Energy Conversion

"People-oriented" is Max Hydro's consistent service principle. We have deep expertise in the hydro power and related derivative products industry, and a profound understanding of the uniqueness of each project—differences in geographical environment, policy requirements, and technical standards determine the high complexity of customer request. Therefore, every Max Hydro project begins with "identifying customized request," accurately capturing the core requirements through in-depth communication between our professional team and the client.

Based on this, we adhere to four principles: Anticipating industry trends, proactively planning technological R&D to ensure the forward-looking nature of our solutions; Optimizing cost structures, by helping clients reduce total life-cycle investment through lean management and supply chain integration; Enhancing collaborative efficiency, by establishing a full-process project communication mechanism to ensure information transparency and efficient execution; and Cultivating long-term cooperation, by building a mutually trusting and win-win strategic partnership with clients based on project delivery quality, laying a solid foundation for future cooperation. From initial solution design to later operation and maintenance upgrades, Max Hydro always stands shoulder-to-shoulder with the clients, providing full-cycle support "from start to finish."

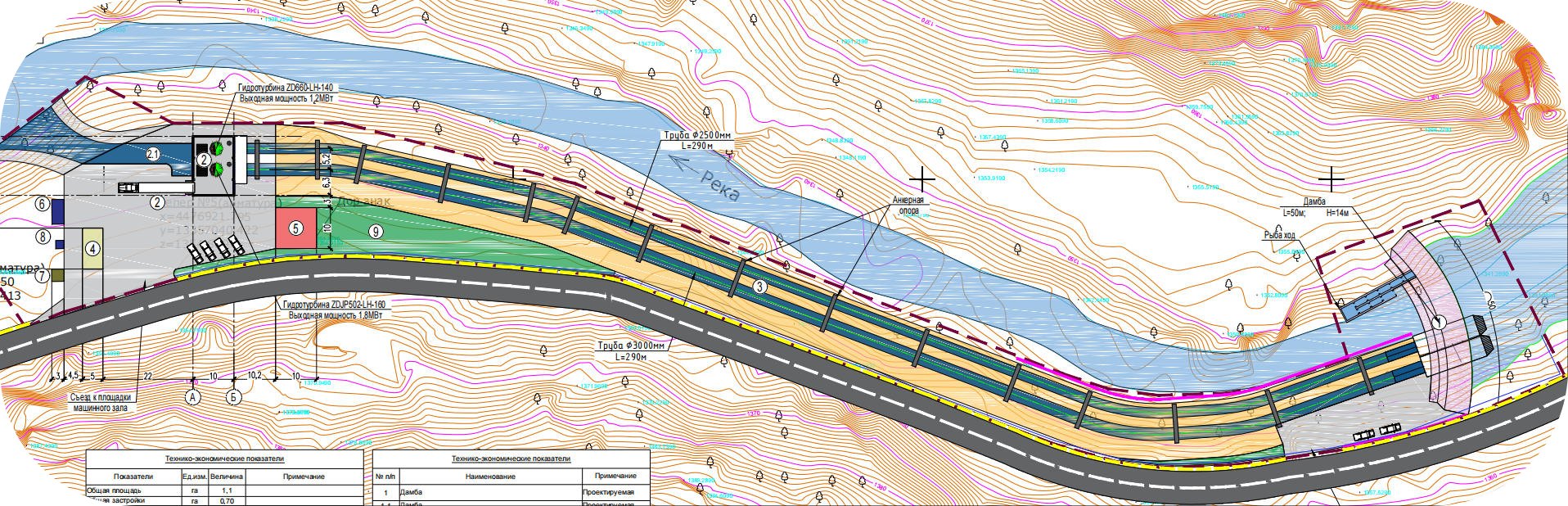

HPP Full-Process Service: Closed-Loop Empowerment from Resource Exploration to Smart Operation and Maintenance. Max Hydro has been deeply involved in the field of hydro power engineering and has built an integrated service system covering the entire life cycle of HPP (Hydro power Plant). With "full-process accompanying service" as the core, it realizes end-to-end closed-loop empowerment from "water resource assessment" to "stable power output".

Preliminary Planning Phase: Utilizing professional methods such as geological surveys, hydro-logical analysis, and environmental assessments, we conduct on-site surveys and resource assessments to provide accurate and effective basic data for new projects, major renovations, and modernization projects, ensuring project feasibility and foresight.

Operation and maintenance support phase: Establish an intelligent operation and maintenance platform to provide full-cycle support such as equipment status monitoring, fault diagnosis, and major overhaul and renovation, combined with regular technical training to help customers achieve efficient power plant operation.

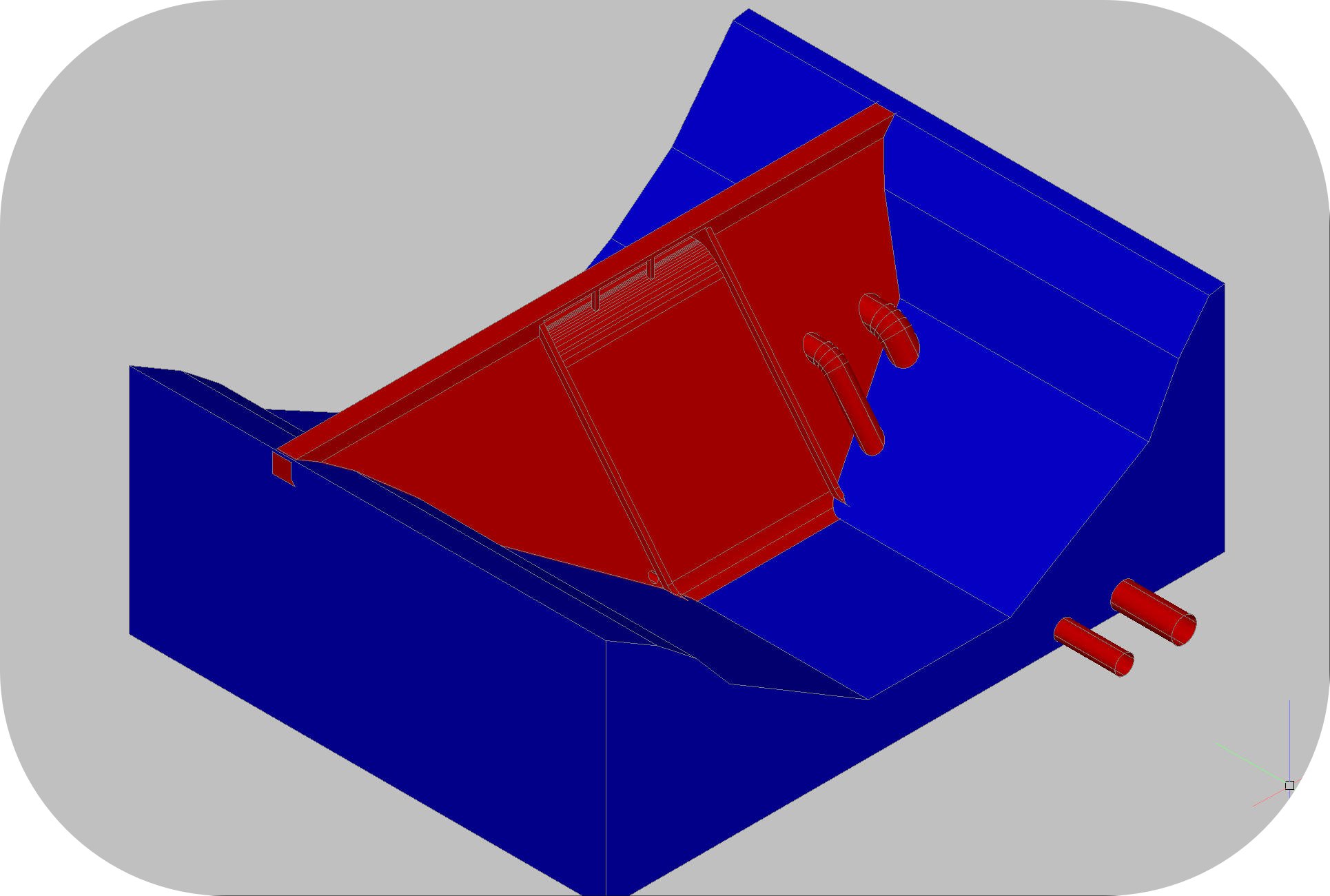

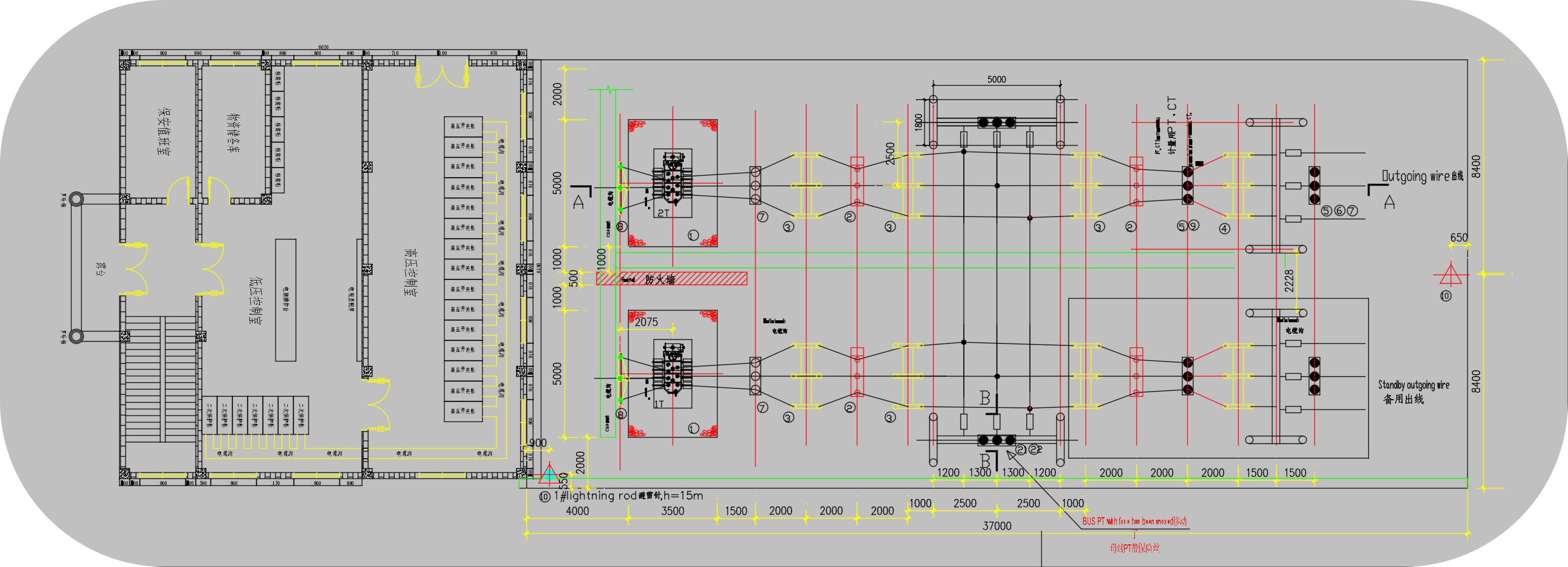

Adhering to the principle of "full transparency management," the project implementation process is synchronized with customers through regular reports, 3D visualization models, and on-site video data, ensuring rapid response to needs and efficient decision-making. From project initiation to five years after power station commissioning, a service loop of "request identification - solution implementation - continuous optimization" has been established, providing full-process support for over 200 hydro power projects worldwide.

3. Manufacturing: The Synergistic Advantages of Scale and Precision

A modern manufacturing base, with three production bases nationwide, covering a total area of over 30,000 square meters of intelligent production workshops, equipped with high-end CNC machine tools, five-axis machining centers, large CNC vertical lathes (maximum machining diameter 8 meters), vacuum heat treatment furnaces, and other high-end manufacturing equipment, with an annual production capacity of over 300 sets of core components for hydro-turbine units and generator sets. There are currently more than 20 stable core component suppliers.

4. Engineering Implementation and Technical Services: Deep Empowerment by a Professional Team

Core team members have an average of over 20 years of experience in the hydro power industry, with 40% holding senior professional titles and over 30 holding professional engineer certifications.

Equipped with a professional mobile service team, we can generally achieve global response within 72 hours, providing on-site machining, welding repair, installation guidance, and other emergency services. We have completed over 200 overseas project technical support operations.

We have established a three-tiered safety management system of "Risk prevention and control - Process supervision - Emergency response," achieving zero safety incidents in large-scale projects for nearly 10 years.

We have jointly established a "Hydro power Talent Training Base" with universities to provide regular training for professional technicians, producing a composite team covering design, operation and maintenance, and management, and providing customized skills training services for clients.

Max Hydro's mission is to "Drive sustainable hydro power development through technological innovation." Through HPP (Hydro Power Plant Management) full-process service capabilities, deep collaboration between R&D and manufacturing, and a global technical service network, Max Hydro provides customers with safe, efficient, and environmentally friendly hydro power solutions. From high-head power plants in Asia to run-of-river projects in Africa, we are committed to becoming our customers' most reliable strategic partner, jointly promoting the upgrading of the clean energy industry.

From the kinetic energy of flowing water to the electricity that lights countless homes, Max Hydro is not only a provider of equipment and services, but also a practitioner of green energy transformation. With "complete solutions" as our framework, "customized services" as our lifeblood, and "professional talent" as our soul, we are committed to injecting sustainable development momentum into the global hydro power industry. In the future, Max Hydro will continue to uphold the philosophy of "people-oriented and innovation-driven," working hand in hand with our customers to build a clean and low-carbon energy future with more advanced technology, higher-quality services, and a more reliable team.