Max Hydro's end-to-end solutions for hydro power plant construction and commercial applications

I. Core Equipment and Services in Hydro power plant Construction A thorough understanding of Max Hydro's various extended construction machinery and supporting equipment used in hydro power plant projects, as well as Max Hydro's commercial application scenarios after the completion of hydro power plant projects, is key to Max Hydro's ability to ensure smooth project progress and achieve expected benefits. The following section details Max Hydro's supply of construction machinery, specialized equipment, and supporting equipment, along with related technical guidance services, used in the hydro power plant construction process. It also introduces Max Hydro's commercial application scenarios after the completion of hydro power plants for clients, providing comprehensive and professional reference for potential clients and ensuring efficient project progress from early construction to later commissioning.

(I) Core Construction Machinery Supply: Max Hydro provides the following specialized machinery for key stages of hydro power plant construction, including earthwork excavation, concrete pouring, and structural hoisting:

Earthwork and Foundation Engineering Equipment

* Large hydraulic excavators (30-50 ton level): Used for dam foundation excavation, riverbed dredging, and raw material extraction at material yards. Equipped with wear-resistant buckets to adapt to complex geological conditions (such as rock and gravel layers).

* Wheel loaders (5-8 ton level): Efficiently transport aggregates, earthwork, and construction materials, supporting multiple operating conditions (such as loading at material yards and feeding concrete batching silos).

* Modular concrete mixing plants (HZS120-HZS240 series): Customized production capacity according to the dam pouring strength, supporting automatic aggregate metering, precise cement and admixture proportioning, and suitable for high-grade impermeable concrete (such as C25/C30 dam concrete).

* Concrete pump trucks and placing booms: Long-boom pump trucks (37-56 meters) enable rapid concrete pouring for dam surfaces, while placing booms, in conjunction with leveling and vibrating equipment, improve pouring uniformity.

* Material processing equipment: Re-bar bending machines, cutting machines, welding robots (for steel structure processing in factory buildings), and aggregate crushing and screening equipment (for aggregate gradation optimization).

• Lifting and Hoisting Equipment

o Tower Cranes: Deployed in dam or power plant construction areas, providing continuous material lifting support with a coverage radius of 50-80 meters.

o Heavy-Duty Drones: 300kg payload, meeting the special requirements of special terrains.

• Tunneling and Pipe Engineering Equipment

o Full-Face Hard Rock Tunnel Boring Machine (TBM): Used for water diversion tunnels and tail-race tunnels, with diameters ranging from 3-10 meters. Equipped with an intelligent guidance system, it can achieve a daily advance of 10-20 meters, significantly shortening the tunnel excavation cycle.

o Cantilever Tunnel Boring Machines (EBZ Series): Suitable for small and medium-sized tunnels or underground power plant excavation, flexibly handling complex geological conditions such as faults and water inrush.

O Automatic spiral tube forming machine: Suitable for steel plates of different models and specifications, it can automatically weld spiral pressure tubes with diameters from 0.5m to 2.5m according to site requirements.

(II) Specialized Equipment and Customized Solutions Max Hydro provides specialized equipment to address the unique characteristics of hydro power plant projects (such as underwater operations, high head control, and precision monitoring):

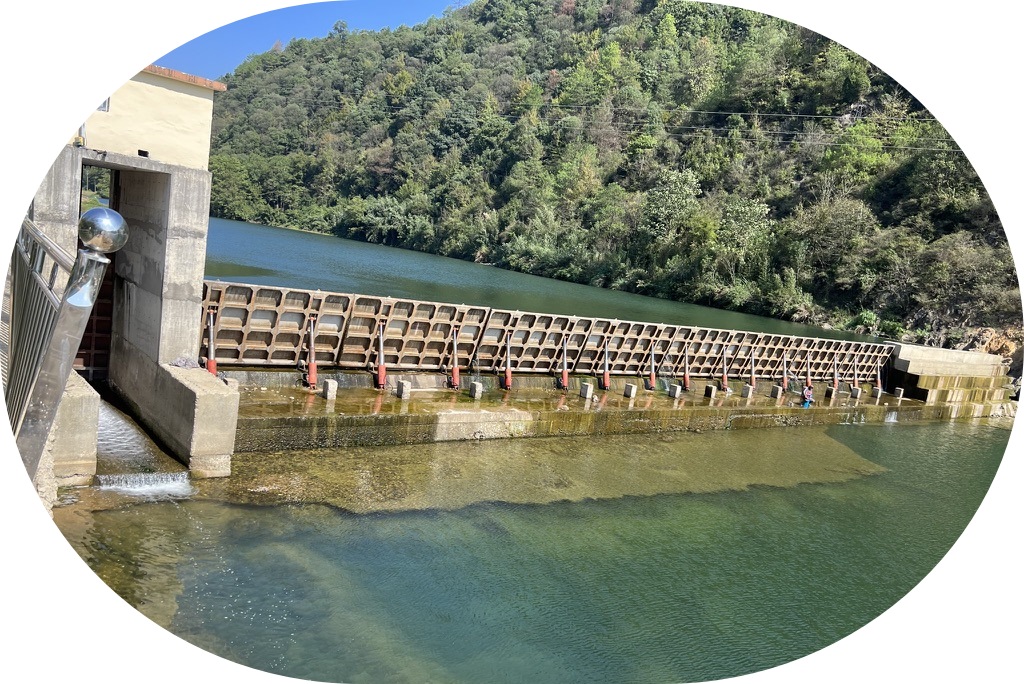

Hydraulic Metal Structure Equipment

o Arc-shaped and planar gates: Customized designs for dam spillway gates and intake gates, made of high-strength stainless steel or carbon steel, suitable for water heads of 50-300 meters.

o Hydraulic gate hoists and winches: Drive precise gate lifting and lowering, supporting remote control and emergency manual operation to ensure rapid flood discharge during flood season.

o Fully automatic slag remover: Automatically cleans debris from the forebay, ensuring clean water supply and reducing labor costs.

Dam Safety Monitoring Equipment

o Automated deformation monitoring system: Includes total station, incline instrument, and piezometer, monitoring dam settlement, displacement, and seepage flow in real time, with data accessed to a cloud platform for early warning.

Specialized Construction Equipment

o High-pressure jet grouting machine: Used for dam foundation anti-seepage curtain construction, forming a continuous anti-seepage wall through high-pressure jetting of cement grout, suitable for sandy and gravelly strata.

(III) Supporting Equipment and Technical Service System

Max Hydro not only provides hardware equipment but also ensures construction efficiency and project quality through comprehensive technical services:

Technical Guidance Services

* **Early Planning Stage:** Providing integrated consultation on "equipment selection + construction proposal," recommending equipment combinations based on project geological conditions (such as seismic intensity and hydro-logical data) to reduce construction risks.

* **Construction Stage Support:**

*Equipment Operation Training:* Providing on-site training (theory + practical) for complex equipment such as TBMs and mixing plants to ensure the construction team masters operation and maintenance skills.

* Real-time Technical Support:* 24/7 remote fault diagnosis; dispatching technical specialists for on-site supervision at key nodes (such as dam closure and unit hoisting).

* ** Post-Construction Support:** Providing equipment maintenance manuals and consumable parts inventory proposals, assisting customers in establishing equipment management systems, and extending equipment lifespan.

II. Commercial Application Scenarios After Hydro power plant Completion Max Hydro helps customers realize the commercial value of hydro power plants through "power generation as the main focus, with added value in multiple scenarios," covering electricity sales, comprehensive utilization, and emerging business areas:

(I) Conventional Scenarios: Clean Power Production and Sales

· Grid-connected power generation: Hydro power plants are connected to the national grid through high-voltage transmission lines, giving them priority in participating in the electricity market transaction. Leveraging the advantages of hydro power's "zero carbon and strong peak-shaving capabilities," they obtain stable revenue.

· Direct supply to industrial users: Providing "direct power purchase" services to high-energy-consuming enterprises (such as aluminum plants and chemical plants), signing long-term power supply agreements to ensure stable electricity costs for customers (5%-10% lower than grid electricity prices).

(II) Innovative Application Scenarios: Advantages and Implementation Conditions of Hydro power in Providing Power and Cooling for High-Energy-Consuming, High-Computing-Power Server Centers in Areas Without Public Power Grids

Core Advantages

In areas without public power grid coverage (such as remote mountainous areas or areas surrounding large hydro power plant), hydro power, as an energy solution for high-computing-power server centers, offers advantages in multiple dimensions, including power supply, cost control, environmental compatibility, and cooling synergy, as detailed below:

1. **Power Supply:** Continuous and stable, adaptable to high energy consumption demands.

**Strong Output Stability:** Hydro power's "base load power" characteristics meet its "zero-interruption" requirements.

**Power Scale Matching:** Large hydro power stations (such as dam-type hydro power stations) can have single-unit capacities reaching megawatts, easily supporting the computing load of hundreds of thousands of kW for a single data center, and can be further expanded through cascade power station combinations.

**Energy Autonomy:** No reliance on the public power grid, avoiding long-distance transmission losses (traditional power grid transmission loss rate is approximately 5%~15%) and the risk of power outages, especially suitable for remote areas not covered by the power grid.

2. **Cost Advantage:** Long-term low prices reduce operational pressure.

**Low Electricity Costs:** Hydro power has zero fuel costs; the main costs are initial construction (dam, generator units), with only maintenance costs required during operation.

**Controllable Land Costs:** Areas without public power grids are mostly remote, with low land rents, suitable for building large-scale server clusters.

3. Environmental Protection and Policy Compatibility: Green and Low-Carbon, In Line with Development Trends

Zero-Carbon Energy Attribute: Hydro power is a renewable energy source with extremely low carbon emissions throughout its entire life cycle, meeting the requirements of the "Green Computing Power" policy.

Preferential Policy Support: Some countries/regions provide subsidies for hydro power development and green data centers in remote areas (such as tax breaks and electricity price discounts), further reducing overall costs.

4. Tail water Cooling: Recycling, Achieving a Closed Loop of "Computing Power-Energy-Cooling"

High-Efficiency and Low-Cost Cooling: The tail water after hydro power generation (i.e., the water discharged after generating electricity through turbines) is typically... The water temperature is relatively low (5~20℃, depending on the water source type: deeper reservoir water is colder, while surface river water is slightly warmer), making it suitable for direct use as a server cooling medium.

Low PUE value achievement: PUE (Power Usage Effectiveness, i.e., total energy consumption/IT equipment energy consumption) is a core indicator for data centers. Traditional data center PUEs are mostly 1.5~2.0, while hydro power tail water cooling can reduce PUE to 1.1~1.2 (close to the theoretical optimal value of 1.0).

Hydro power provides a three-in-one solution of "power-cooling-environmental protection" for high-performance server centers in areas without a public power grid.

(III) Comprehensive Business Scenarios: Green Energy Synergy and Carbon Asset Operation

• Hydro-Solar/Wind-Hydro power Complementary Projects: In conjunction with solar power plants and wind farms, hydro power plants leverage their rapid start-up and shutdown capabilities to mitigate fluctuations in renewable energy generation (e.g., hydro power supplementing power when solar output is insufficient at night), increasing the grid's capacity to accept renewable energy and generating revenue from peak-shaving ancillary services.

• Carbon Trading and Green Certificate Development: As clean energy projects, hydro power plants can generate additional revenue through green certificate trading or participation in international carbon markets.

• Energy Storage Application Scenarios: From Grid Stabilization to Energy Revolution

The application of hydro power plants and energy storage systems has expanded from traditional peak shaving to multiple fields, becoming "stabilizers" and "regulators" of the power system.

1. Grid Peak Shaving and Frequency Regulation

Peak Filling: Pumped storage at night for daytime power generation, balancing peak-to-valley load differences; Dynamic Frequency Regulation: Maintaining grid frequency stability through rapid start-up and shutdown of generating units.

2. Renewable Energy Integration

Volatility Smoothing: Combining hydro power, wind power, solar power, and other intermittent power sources, smoothing the output curve through energy storage systems.

3. Emergency Backup and Black Start

Emergency Power Supply: Rapidly starting power generation during grid failures, ensuring critical load black start capability: Self-starting without external power supply, helping the grid recover.

4. Electricity Market Trading

Price Arbitrage: Utilizing peak-to-valley price differences and generating revenue during peak periods. Ancillary Services Market: Providing services such as frequency regulation and backup to generate additional income.

III. Summary

Max Hydro provides comprehensive support across the entire supply chain, encompassing equipment supply, technical services, and case-based solutions. This ensures efficient construction and safety management during the hydro power plant construction phase while also helping clients unlock diversified commercial value after completion. Whether it is traditional electricity sales, comprehensive water resource utilization, or emerging carbon asset management, Max Hydro offers customized solutions, providing solid support for clients to achieve their goals of "high-quality engineering and optimal benefits."